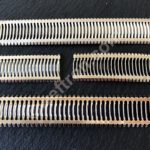

Louvered Contacts

for assembly on pins, in sockets or in flat connectors

Torsion Spring Type

Louver_tron 317

17,5mm wide CuBe louvered contacts with multiple contact points in 2.5mm spacing. more...

View or download data sheet here: Louver_tron 317

Louver_tron 313

13mm wide CuBe louvered contacts with multiple contact points in 2mm spacing ...more...

View or download data sheet here: Louver_tron 313

Louver_tron 217

17,5mm wide CuBe louvered contacts with multiple contact points in 2mm spacing... more...

View or download data sheet here: Louver_tron 217

Leaf Spring Type

Louver_tron 512

12mm wide contact strip with multiple contact points...more...

View or download data sheet

here: Louver_tron 512

Louver_tron 508

8mm wide CuBe contact strip with multiple contact points...more...

View or download data sheet here: Louver_tron 508

Louver_tron 505

5mm wide CuBe contact strip with multiple contact points...more...

View or download data sheet here: Louver_tron 505

Multi Component Type - Increased Conductivity

Louver_tron 108

9.8mm wide CuBe sprung carrier tape with individual copper contact plates...more...

View or download data sheet here:

Louver_tron 108

Louver_tron 112

12mm wide stainless steel sprung carrier tape with individual copper contact plates...more...

View or download data sheet here:

Louver_tron 112

Louver_tron

is a product family of contact inserts within the weftron product range of different electrical contact band or electrical contact strip designs. When inserted between precision machined metal parts they will provide precisely defined spring loaded contact points for high performance electrical connections. The design differences between the available contact bands are width and thickness as well as features in the individual louvers. The basic common principle of all Louver_tron contact strips is the very dense arrangement of consecutively and in parallel arranged sprung contact elements. In the final application, when functioning as multiple electrical contacts points between two conducting surfaces, these multiple current paths have significant advantages over contact systems with less or with only two current paths.