Louvered Contact Band

- Materials

The predominantly used material for louvered contact band is a special Beryllium Copper Alloy. Especially when speaking about - Single Component Contact Bands -. Although pure grade copper would offer much better electrical conduction the mechanical spring properties of hardened CuBe alloy are required for the functionality of a pluggable electrical connection. Albeit the lesser electrical conductivity CuBe is a very good thermal conductor. Beneficial for heat soaking the temperature away to the metal components of the connector that will develop by material inherent electrical resistance at each contact point .

Contact resistance

Further improvement to lower contact resistance may be achieved in selecting suitable surface treatments for the louvered contact band. Any oxide layer on metal surfaces will act as an electrical insulator. Although Louver_tron louvered contact band is designed to break this oxide layer and wipe it away from the contact points during the mating of the connecting parts the oxide layer of bare copper is a quite hard. Increasing the spring force will help in wiping such hard insulating layers. This however comes at the cost of damaging the surface of the mating component after a relatively low number of mating cycles.

For this reason it is recommended to use surface platings on the metal components and on the contact band. For high power low resistance electrical connection silver is the preferred choice. The conductivity of silver is ranking among the highest and the oxide layer of silver is quite soft. Allowing an optimum setting of spring force for high performance and long contact life.

Conductivity

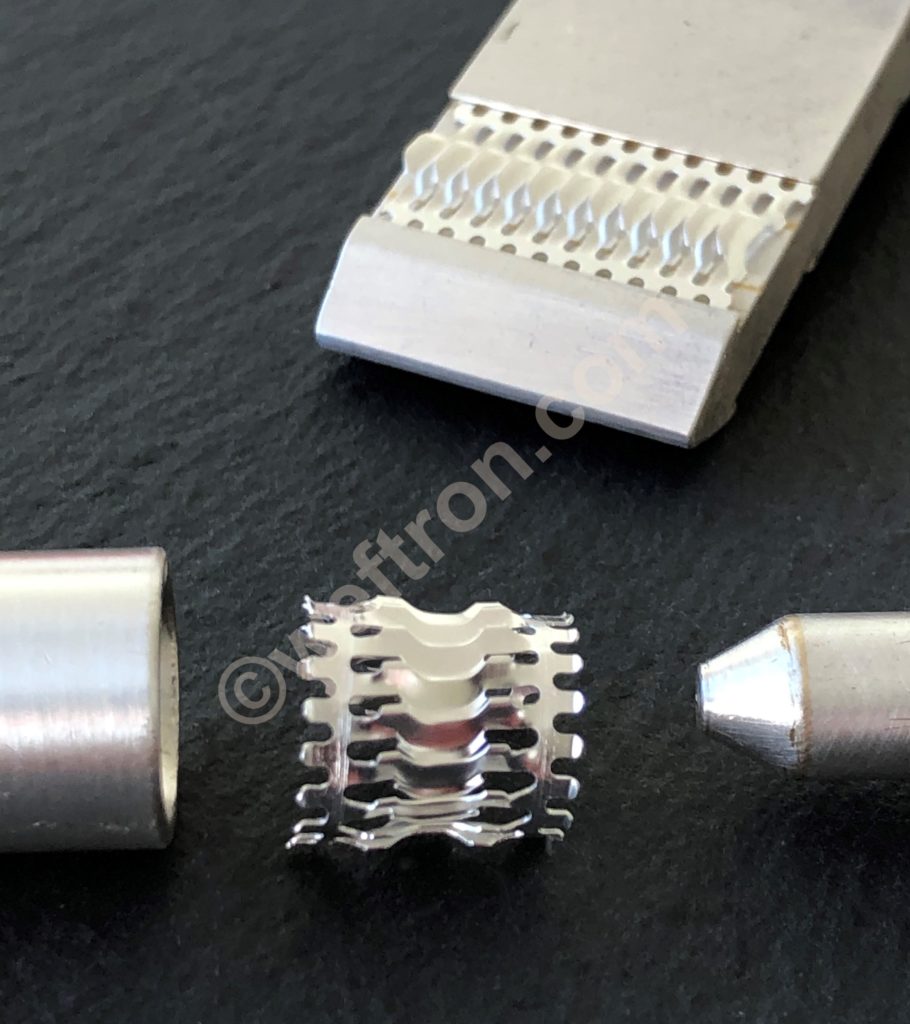

Using pure grade copper for the conducting element between the connector components increases conductivity as compared to beryllium copper. However copper does not provide the necessary spring force that is functionally necessary. The way to solve this is by creating - Multi Component Contact Bands. Such such as weftron.com Louver_tron 112 or Louver_tron 108.

The spring feature in these Multi Component louvered contacts is provided by a separate carrier tape. Either made of stainless steel or of CuBe on which individual copper contact plates are mounted. Here again the surface treatment of choice for the contact plates is silver. The carrier tape does not necessarily require surface treatment. Unless when used in chemically hostile environments and gold will have to be used to protect all surfaces.

From an aspect of production effort and cost - Multi Component Contact Bands - are much more complicated to produce than contact bands made from a single metal strip. Nevertheless there are applications when such - Multi Component Contact Bands - have no matching alternative. Due to their individual contact plates higher electrical and thermal conductivity and their larger mass they fulfill specifications with high short circuit currents when single component contact bands would fail.

Continue reading about the function of louvered contacts ....

Louvered Contact Bands – Materials Read More »