What is Louver_tron contact band and what are the benefits of multiple contact points in a connector?

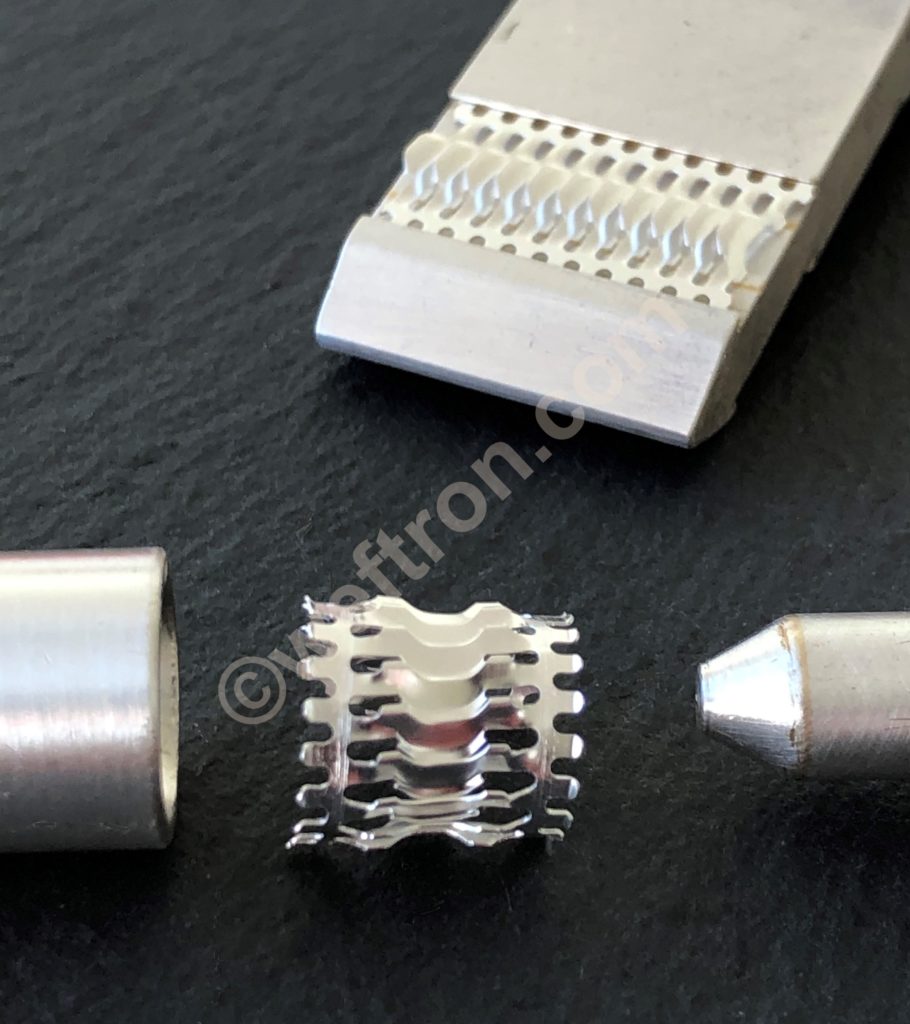

The basic common principle of all Louver_tron contact strips is to provide multiple contact points in a very dense arrangement of consecutively sprung contact elements that are arranged in parallel.

Louver_tron is a product family within the weftron product range of electrical contact band and electrical contact strip designs.

When inserted between precision machined metal parts they will provide precisely defined spring loaded contact points. For high performance electrical connections a high number of contact points is obviously a key requirement. Furthermore the physical width, thickness and surface treatment of the required contact bands need to be considered. Therefore weftron contact bands with dense arrangements of contact points are available in several variations. Depending on the application and performance requirements different weftron louvered contacts or contact lamella may be selected.

The basic common principle of all Louver_tron contact strips is to provide multiple contact points in a very dense arrangement of parallel, consecutively arranged sprung contact elements. In absence of a defined technical term, the individual sprung contact elements are commonly compared with similar looking technical elements. Hence also referred to as contact lamella, louvered contacts or crown springs. In the final application these multiple current points have significant advantages over contact systems with less or with only one or two current paths.

Any contact system and hence any connector will cause a certain resistance in an electrical system. In critical and demanding applications it is essential to assure the least restriction to current flow. So the main design inherent advantage of Louver_tron louvered contact band is easily explained with Ohm’s law. In a system of electrical resistors arranged in parallel, the total resistance is a function of:

(average resistance per resistor) / (number of resistors)

So the resistance calculation of a contact system using Louver_tron is:

(average contact resistance of individual louvered contact) / (number of louvered contacts).

Find out how you can easily integrate your own design of a High Power Connector or Low Loss Connector using Louver_tron louvered contact bands and add value to your overall design here…..

– What are the benefits of multiple contact points in a connector? Read More »